Your additive manufacturing production partner

aerospace

aerospace

Producing complex geometries with intricate internal lattices to maintain strength and reduce weight

automotive

automotive

Delivering lighter parts that are optimised for performance ensuring functional strength and structural integrity

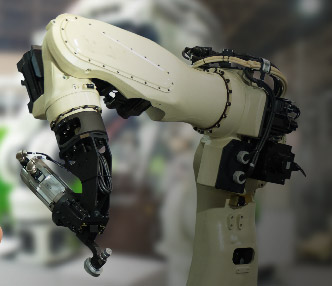

industrial

industrial

Achieving quality builds with high finishes is now a reality with additive manufacturing

motorsport

motorsport

Reducing weight and enhancing structural integrity and strength with one single manufacturing process

oil & gas

oil & gas

Opening a gateway to the future with additive manufacturing ensuring standards are met

defence

defence

Using additive manufacturing to reduce weight in moving objects and increasing efficiency

3T Additive Manufacturing offer market leading polymer and metal additive manufacturing (3D printing) to a wide range of industries. We offer supply chain solutions providing parts that reduce mass, weight, cost and lead times whilst maintaining safety through prototype, development and serial production.