Revolutionising Copper through additive manufacturing

We’re excited to be part of a world first in 3D printing through our collaboration with Launcher and EOS, revolutionising the way we use additive manufacturing to enhance the performance of Space components.

From Apollo 11’s first manned mission to land on the moon in 1969, to the first landing on Mars this week, the space industry has made huge advancements in not only the technology used, but also the understanding of the requirements needed to break the boundaries.

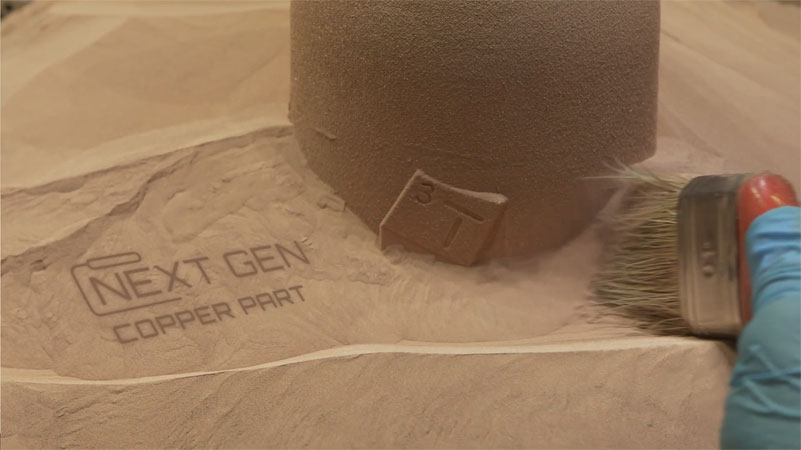

Working in collaboration with Launcher and EOS to manufacture the Copper rocket engine has established huge opportunities not only for 3T, but also for the Space industry. Its high conductivity, efficient cooling and durability have been significantly enhanced through AM. Complex internal structures were created in our facility, delivering world class results.

Take a look at our 3D printed Copper rocket in action.

Recent News

07th January 2020